Automated Sanitization Processes for Commercial Float Facilities

The Importance of Automated Sanitization in Commercial Float Facilities

Commercial float facilities, where individuals experience sensory deprivation in saltwater-filled tanks, have gained popularity for their therapeutic benefits. However, maintaining a hygienic environment is crucial to ensure user safety and prevent contamination. Automated sanitization processes have emerged as a game-changer in this industry, offering efficient, consistent, and thorough cleaning solutions. Unlike manual cleaning, which is prone to human error, automated systems use advanced technologies to eliminate pathogens, reduce downtime, and enhance operational efficiency. This section explores why automated sanitization is essential for float facilities and how it addresses the unique challenges of maintaining such environments.

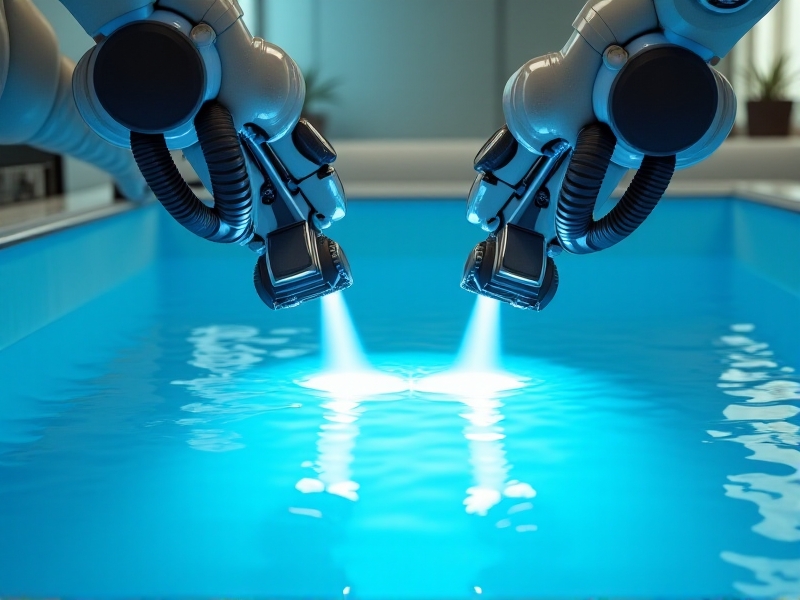

How Automated Sanitization Systems Work

Automated sanitization systems in float facilities leverage a combination of robotics, sensors, and chemical agents to ensure thorough cleaning. These systems are designed to target hard-to-reach areas, such as the corners of float tanks and filtration systems, which are often missed during manual cleaning. Sensors detect contamination levels and adjust the sanitization process accordingly, ensuring optimal results. Additionally, these systems can be programmed to operate during off-peak hours, minimizing disruption to facility operations. This section delves into the mechanics of automated sanitization systems, highlighting their components, functionalities, and the science behind their effectiveness.

Benefits of Automation for Float Facility Hygiene

Automated sanitization offers numerous advantages for commercial float facilities. First, it ensures consistent cleaning standards, reducing the risk of contamination and enhancing user safety. Second, it saves time and labor costs, allowing staff to focus on other critical tasks. Third, automated systems often use eco-friendly sanitizing agents, aligning with the growing demand for sustainable practices. Furthermore, these systems provide detailed logs of sanitization activities, which can be invaluable for compliance and auditing purposes. This section examines the tangible and intangible benefits of automation, demonstrating how it transforms hygiene management in float facilities.

Challenges and Considerations in Implementing Automation

While automated sanitization systems offer significant benefits, their implementation is not without challenges. The initial investment can be substantial, and facilities must ensure that staff are trained to operate and maintain these systems. Additionally, compatibility with existing infrastructure and the selection of appropriate sanitizing agents are critical factors to consider. This section discusses the potential hurdles in adopting automated sanitization and provides practical tips for overcoming them, ensuring a smooth transition to this advanced technology.

Future Trends in Float Facility Sanitization

The future of sanitization in commercial float facilities is poised for innovation. Emerging technologies, such as UV-C light sanitization and AI-driven cleaning systems, are expected to revolutionize the industry. These advancements promise even greater efficiency, reduced environmental impact, and enhanced user experiences. Additionally, the integration of IoT (Internet of Things) will enable real-time monitoring and predictive maintenance, further optimizing facility operations. This section explores the cutting-edge trends shaping the future of automated sanitization and their potential impact on the float therapy industry.

Case Studies: Success Stories of Automated Sanitization

Several commercial float facilities have successfully implemented automated sanitization systems, reaping significant benefits. For instance, a facility in California reported a 30% reduction in downtime and a marked improvement in customer satisfaction after adopting robotic cleaning systems. Another case study from Australia highlights how automation helped a facility achieve compliance with stringent health regulations. This section presents real-world examples of successful implementations, showcasing the transformative impact of automated sanitization on float facilities.

Conclusion: The Path Forward for Float Facility Hygiene

Automated sanitization processes are revolutionizing the way commercial float facilities maintain hygiene. By combining advanced technology with efficient cleaning methods, these systems ensure a safe and enjoyable experience for users while streamlining operations for facility managers. As the industry continues to evolve, embracing automation will be key to staying competitive and meeting the growing demand for high-quality float therapy services. This section summarizes the key takeaways and encourages facility owners to explore the potential of automated sanitization for their businesses.